In the modern era of rapid purchase and construction of the Internet of Things, forklifts play a crucial role in supply chain management due to their ability to efficiently handle and move materials within warehouses, distribution centers, manufacturing facilities, and other logistical environments. How to choose a correct battery for your forklift is particularly important. In the battery market, the dominant technology is lead, followed by lithium (especially lithium iron phosphate). Although lead has existed for more than a century, lithium iron phosphate technology has achieved greater success in the application market with multiple shifts and high energy demand due to the advantages of high rate charge and discharge, maintenance-free, long life, etc.

How to choose the correct battery size is critical to ensure efficient operation of forklifts.

1. Voltage and Ampere Hours

Forklift batteries usually have four voltages to choose from, choosing the right one is the most important part of battery selection. An oversized battery can cause serious and irreversible damage to your truck, so it's important to know what type of voltage your vehicle can handle. Typically, the voltage requirements are marked on the spec board of most forklift trucks.

2. LiFePO4 Battery size

You need to measure the battery compartment of the forklift and make sure the battery is properly installed. Lithium iron phosphate battery need to be properly matched to the battery compartment, and batteries that are too large or too small can be a safety hazard.

3. Battery weight

Check the spec sheet or spec plate for minimum and maximum battery weight requirements for your vehicle. If you choose a battery that weighs more than the maximum weight, you risk putting unnecessary stress on various device components and may even void your warranty.

In many cases, the battery also acts as a counterbalance for the truck, and a battery that is lighter than the minimum required weight can reduce the truck's lifting capacity and create safety concerns. When replacing the battery on any forklift, a new spec sheet may be required for instructions. The battery of an electric forklift acts as a counterweight to the machine and is critical to its lifting capacity.

What power of LiFePO4 battery is suitable for me?

It all depends on demand. Performance is critical to the success of your operation, and every facility should have its battery/charger system analyze a vehicle's power needs and duty cycle. A key way to quantify power requirements is to determine the equivalent battery unit (EBU) required.

What is the opportunity to charge a forklift battery?

Opportunistic charging is a system that allows a battery to be charged multiple times over a duty cycle (usually eight hours). This allows one battery to stay in the vehicle much longer than conventional power sources. The goal is to eliminate the hassle of changing batteries during shifts.

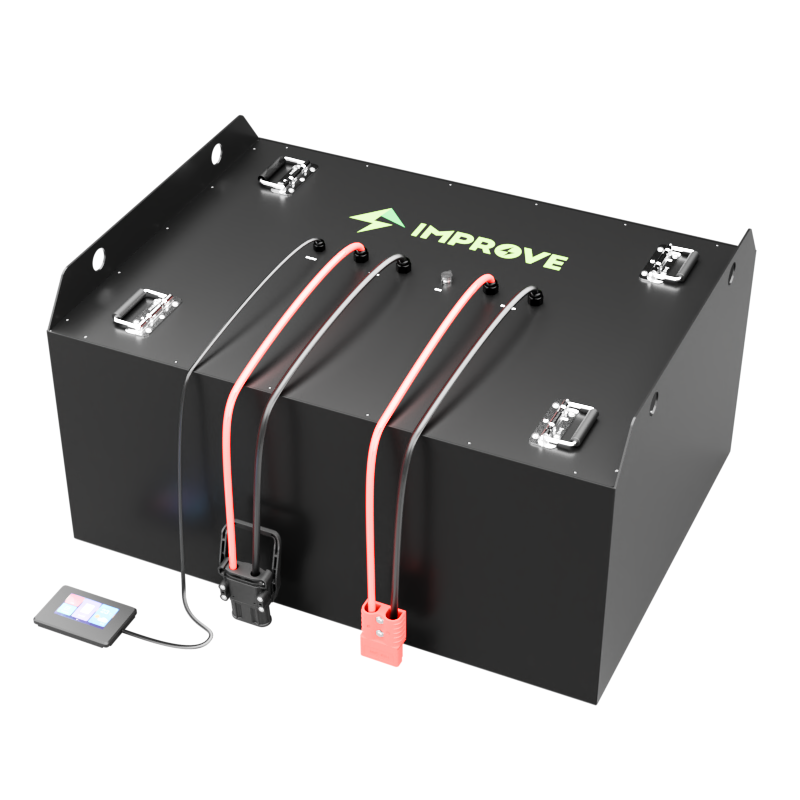

In a warehouse, changing batteries by running forklifts through multiple shifts each day is an extremely taxing job. You need to take the time to charge them and let them cool down, which adds a lot of time. Now, with the advent of IMPROVE Lithium Iron Phosphate batteries, opportunistic charging is becoming more and more popular.

Both lead-acid and lithium-ion batteries can be recharged using opportunity. When taking advantage of the opportunity to charge lead-acid batteries, you may experience disadvantages such as reduced battery life and increased maintenance requirements. These shortcomings are the reason many facilities are transitioning to lithium-ion batteries. Unlike lead acid, the life of IMPROVE LiFePO4 batteries can be extended when opportunity recharges.

Many companies use forklifts more frequently in multi-shift operations to meet demand. IMPROVE Lithium-ion battery packs combined with opportunistic charging can save time and increase productivity. IMPROVE BATTERY, the best partner for your forklift. We will provide effective forklift lithium batteries that meet market positioning according to the needs of each customer.