Lithium iron phosphate battery charging skills

The full name of lithium iron phosphate battery is lithium iron phosphate lithium ion battery. Because of its performance is particularly suitable for power applications, in the name of the addition of "power", namely lithium iron phosphate power battery. Some people call it an "iron lithium power battery." Do you all know how to charge lithium iron phosphate? Here are the charging skills of lithium iron phosphate batteries.

- 1. first of all, we need to understand the structure and working principle of lithium iron phosphate batteries, LiFepO4 as the positive pole of the battery, connected to the battery positive electrode by aluminum foil and polymer is among the diaphragm, which separates the positive and negative, but cannot by lithium ionic and electronic, right is composed of carbon (graphite) battery cathode, the copper foil and negative connection of the battery. Between the upper and lower ends of the lithium iron phosphate battery is the electrolyte of the battery, which is enclosed by a metal shell. When the lithium iron phosphate battery is charging, the lithium ions in the positive electrode migrate to the negative electrode through the polymer membrane. During the discharge, lithium ions from the negative electrode migrate to the positive electrode through the diaphragm. Lithium-ion batteries are named after the movement of lithium ions back and forth between charges and discharges.

- When lithium iron phosphate battery is charged, lithium ions migrate from the surface of lithium iron phosphate crystal to the crystal surface, under the action of electric field force, enter the electrolyte, pass through the diaphragm, and then migrate to the surface of graphite crystal through the electrolyte, and then embed in the graphite lattice. At the same time, the electron flows to the aluminum foil collector of the positive electrode through the conductive body, the copper foil collector of the negative electrode through the electrode ear, battery pole, external circuit, negative pole and negative ear, and then flows to the graphite negative electrode through the conductive body, so that the charge of the negative electrode reaches balance. After the lithium ion is removed from the lithium iron phosphate, the lithium iron phosphate is converted to iron phosphate.

- When the lithium iron phosphate battery is discharged, lithium ions are removed and embedded from the graphite crystal, enter the electrolyte, pass through the diaphragm, migrate to the surface of the lithium iron phosphate crystal through the electrolyte, and then re-embed into the lattice of lithium iron phosphate through the surface. At the same time, the lithium iron phosphate battery flows to the copper foil collector of the negative electrode through the conductive body, the aluminum foil collector of the positive electrode through the electrode lug, the battery negative pole, the external circuit, the positive pole and the positive pole lug flow to the positive electrode of the battery, and then flows to the positive electrode of lithium iron phosphate through the conductive body, so that the charge of the positive electrode reaches balance.

Special attention: it is reminded that lithium iron phosphate battery should be waterproof and dustproof when used, so there should be no water in the storage place, which will affect the performance and service life of the battery.

Correct charging method of lithium iron phosphate battery pack:

CCCV charging method is recommended for lithium iron phosphate battery pack, that is, constant current and constant voltage. Constant current is recommended at 0.3c. When the voltage of lithium iron phosphate battery pack reaches 3.65V, use 3.65V constant voltage to charge. When the charging current is lower than 0.1c (or 0.05c), stop charging, that is, the battery is full. It is recommended not to charge at too high a voltage. After adjusting the voltage, ensure that the charging current is below 0.5C, which is good for the battery.

Generally, the upper charging voltage of lithium iron phosphate battery is 3.7-4V, and the lower discharging voltage is 2-2.5V. Considering the discharge capacity, discharge median voltage, charging time, percentage of constant current capacity and safety, the charging scheme of constant current and constant voltage is adopted for lithium iron phosphate battery pack. For lithium iron phosphate battery pack, it is reasonable to set the charging limit voltage at 3.55-3.70 V, the recommended value is 3.60-3.65 V, and the discharge limit voltage is 2.2-2.5 V.

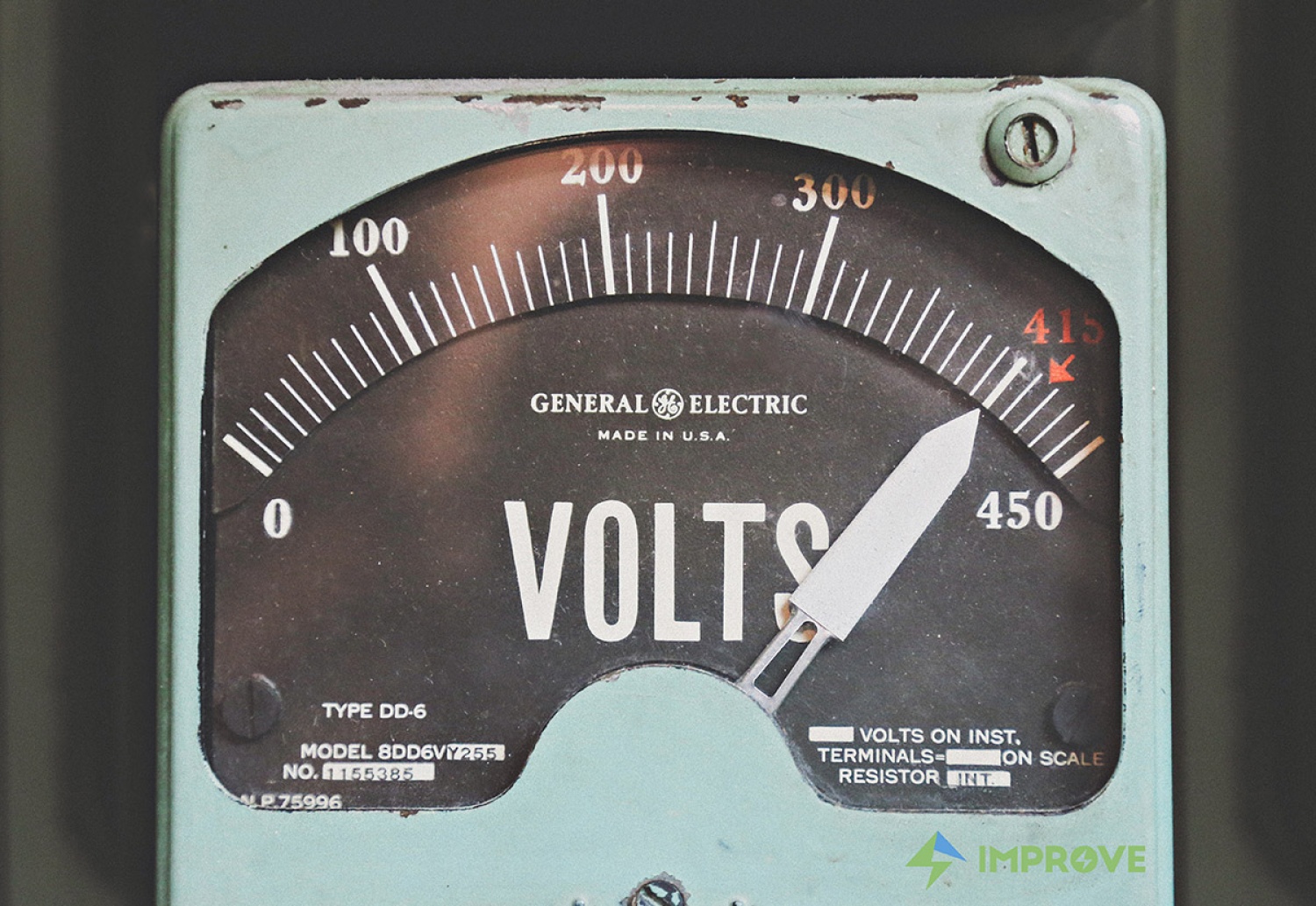

The charger of lithium iron phosphate battery pack is different from ordinary lithium battery. The maximum termination voltage of a normal lithium battery is 4.2 VOLTS; The lithium iron phosphate battery pack is 3.65 volts. When the lithium iron phosphate battery pack is charged, it is the line connected by the balance charging plate. It is generally charged in series directly from both ends. The voltage of the charger is greater than the voltage of the battery pack. The voltage of each single cell is detected by row, which is equivalent to parallel regulator tubes. The charging voltage of the single cell will not exceed the regulator value, while other single cells continue to be charged through the regulator tube by bypass.

Because at this time, the electric charge of each cell is close to full and it is just balancing each cell, so the charging current is small and the supplement balances each cell to be full. The charger can only protect the voltage at the end of the battery pack, and the balance charging plate is to ensure that each monomer is charged and each monomer is full, and the whole lithium battery pack can not be stopped because there is a battery full.

Charging method of lithium iron phosphate battery pack

- Constant voltage charging method: In the charging process of lithium iron phosphate battery pack, the output voltage of the charging power supply remains constant. With the change of the charge state of the lithium iron phosphate battery pack, the charging current can be automatically adjusted. If the voltage constant value specified is appropriate, the complete charging of the power battery can be guaranteed, and the gas extraction and water loss can be minimized. This charging method only considers the change of battery voltage, which is a single state, and cannot effectively reflect the overall charging status of the battery. Its initial charging current is too high, often causing damage to the power battery. Given this disadvantage, constant voltage is rarely used to charge lithium iron phosphate batteries.

- Constant current charging method: The charging current of lithium iron phosphate battery pack is kept constant by adjusting the output voltage during the whole charging process. Keeping the charging current unchanged, its charging rate is relatively low. The control method of constant current charging is simple, but the acceptable current capacity of lithium battery pack decreases gradually with the charging process. In the late charging period, the receiving capacity of power battery decreases, and the utilization rate of charging current decreases greatly. The advantages of this method are simple operation, convenient, easy to implement, easy to calculate the charge quantity.

- Constant current and constant voltage charging method: this charging method is a simple combination of the above two. In the first stage, constant current charging method is adopted to avoid excessive charging current at the beginning of constant voltage charging. In the second stage, constant voltage charging method is adopted to avoid the phenomenon of overcharging caused by constant current charging. The lithium iron phosphate battery pack, like any other sealed rechargeable battery, should be charged to control, not overcharge, otherwise it is easy to damage the battery. The charging method of lithium iron phosphate battery is constant current and limited voltage.

(4) Chopper charging method: The chopper method is used to charge lithium iron phosphate battery pack. Under this method, the constant current source current, and switch tube to control, to make it open again after a period of time off for a period of time, cycle, the advantage of this approach is that when through an external circuit for the battery, the battery inside the ion needs to have certain response time, if continued to charge of it, may reduce the potential of its capacity. After charging for a period of time, adding a turn-off time can make the ion generated at the battery poles have a diffusion process, making the battery has a "digestion" time, which will greatly increase the utilization rate of lithium iron phosphate battery pack and improve the charging effect.